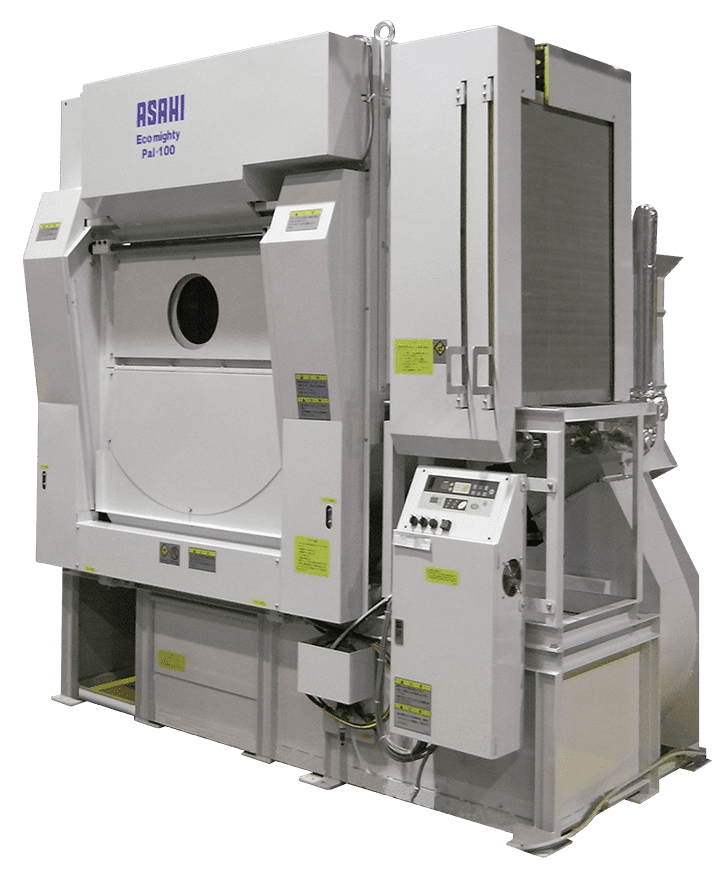

Save the factory costs with

our Energy Saving Dryer

Standard Load Capacity

100kg

The Successors to ASAHI’s “Direct Axial Blow” system

and our “Side-by-side Installation” system.

Standard Load Capacity

60kg

A Revolution in Drying!

Drying time and steam consumption approximately 50% less than conventional machines

Standard Load Capacity

30kg

Installing a new user- friendly microcomputer

Standard Load Capacity

20〜30kg